I did get it to work, but the results left me with some funky holes. I had to download a different one (the Conda build) and the tool was there. Apparently the build I have does not use that.

I did go back and do some more research for why the Unwrap Mesh command wasn't there. I apologize about the Zip file, but I have a Master File that keeps track of my calculations stored in a folder above the part and this was the only way I knew how to keep the links together when uploading. Is there a better way for me to make these modifications to the shape that won't make it fail? I've uploaded the file for someone to play with. Is this a limitation of the tool that it can't unbend something that has been trimmed with a Sketch and Pocket? It seemed to work with the holes I made on the top. Basically it fails when I try to cut out part of the shield.

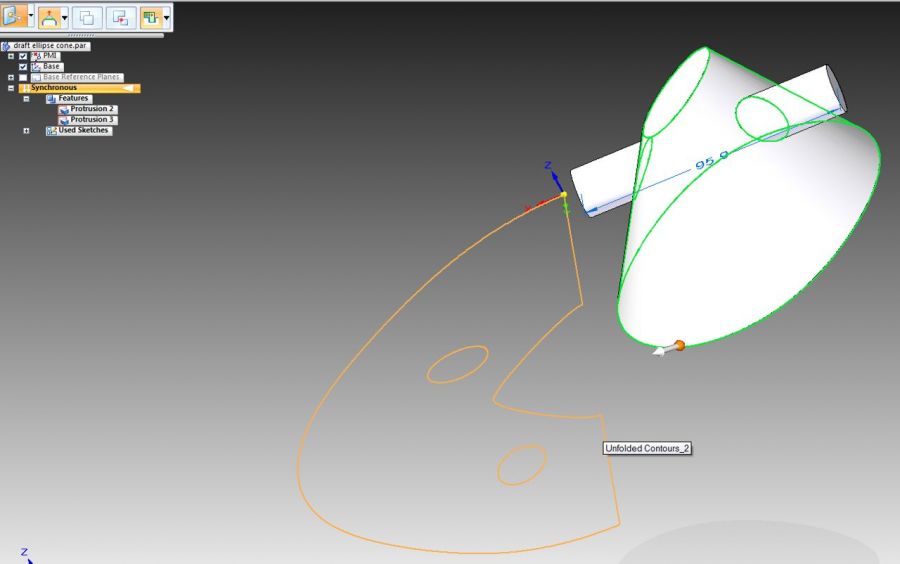

I went back and started deleting steps of my build and kept trying the Unfold tool until it started to work. I then went in and tried to use the Unfold command in the Sheet Metal WB and it started to work and then told me it was failing. I went back and recreated my shield using that tool and Part Design and I again had a nice model of the shield I wanted to build. I did some more digging and found the Sheet Metal WB which looked like it would even be a better option for what I wanted to do. Well, all went well until I found that my version of FreeCAD doesn't appear to have the Unwrap Mesh option in the drop down menu. So as I dug through the internet and I ended up finding a video on how to take a 3D drawing, use the Draft WB to create a Facebinder of the object, go to the Mesh WB create a Mesh from shape, and then I was to use the Unwrap Mesh command to flatten it out, take it to TechDraw and then export the shape from there. I figured there had to be a better way to convert my 3D drawing. The metal shop actually downloaded FreeCAD and then tried using it to manually draw up a 2D version on their program. Needless to say, I was a bit bummed since I went through all the work to create it in 3D.

After talking to them, they figured out that they were only using the 2D version of AutoCAD and could not import my 3D model. I then exported the 3D model of it as a STEP file so the metal shop could use it in their AutoCAD program. I got it all set up the way I wanted using the Parts Design tool and was happy with my result. I've built a shield that I was going to have our local metal shop cut out and build.

0 kommentar(er)

0 kommentar(er)